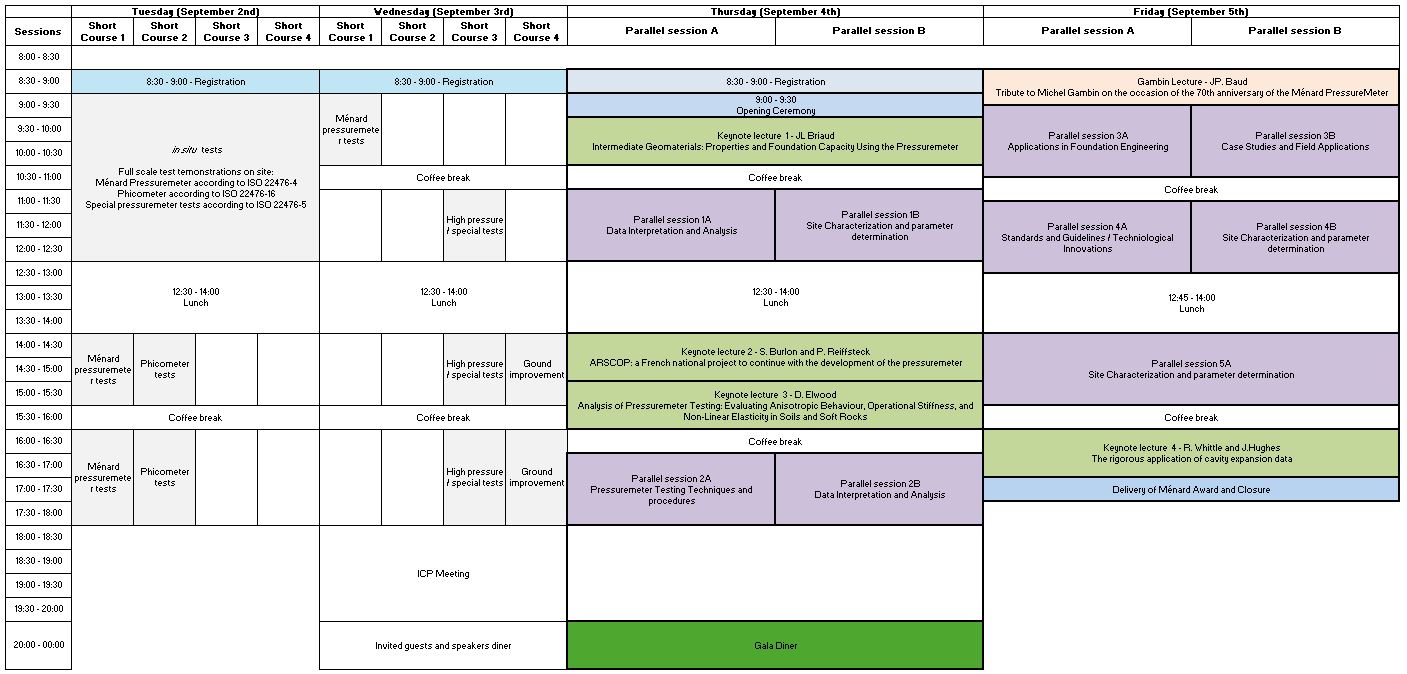

Short courses

Four short courses will take place on the 2 and 3 September 2025. Theoretical sessions will follow a practical session on site, where participants will have the opportunity to see the testing equipment in action, performing real tests. The tests performed will then be treated and discussed during the theoretical courses.

In situ tests covering different testing techniques treated during the short courses will run in parallel on the same testing site: Ménard pressuremeter, high definition/high pressure pressuremeter, phicometer.

Short course 1: Ménard pressuremeter tests

By Julien Habert, Jean-Pierre Baud, Jacques Monnet

In-situ full scale tests demonstration on Belval site: September 2nd 2025 – 09.00 to 12.30

Courses: September 2nd 2025 – 14.00 to 18.00 and 3rd 09.00 to 10.30 – Duration: 5.30 hours, including breaks

September 2nd 2025, 14.00 to 16.00 : Ménard pressuremeter tests

1. Testing equipments and protocols (Jean-Pierre Baud)

- Overview of testing materials

- Types of P-V control units, probes, etc. used on Belval site

- Other current equipments (probes, control units type A, B, C, etc.)

- Placing the pressuremeter probe in the ground

- Overview on Annex C of EN ISO 22476-4, tables C1& C2

- Focus on Table C2 “best methods”

- Drilling logs (MWD) of SP1 & SP2 made during the morning

- Ménard testing programme

- Loading programme in ISO 22476-4

- Execution of the programme by 1) manual operator or 2) automatic regulation

- Recordings and accuracy

2. Interpretation of Ménard pressuremeter tests (Jean-Pierre Baud)

- Background

- Pressure loss correction

- Volume loss correction

- Corrected pressuremeter curve review

- Obtention of pressuremeter creep pressure

- Obtention of Ménard pressuremeter modulus

- Obtention of Ménard pressuremeter limit pressure

- Interpretation of tests performed on September 2nd 2025 morning

- Raw measurements and calibrations given to participants

- Corrected curves obtained on a PMT software (projection of software interface)

- Choice of P1-P2 range 1) by participants (computer or pocket calculator) 2) by software and derivation of Ménard pressuremeter modulus

- Numerical fitting of curves, extrapolation and derivation of Ménard pressuremeter limit pressure

- Obtention of creep pressure

- Edition of a pressuremeter log

- Additional examples (atypical tests, uncomplete tests, etc.)

September 2nd 2025, 16.30 to 18.00 : Obtention of shear resistance

3. Obtention of shear resistance (Jacques Monnet)

- Theoretical background

- Accuracy of pressuremeter results

- Determination of angle of shear friction (Principles, results)

- Determination of undrained cohesion (Principles, results)

- Interpretation of tests performed on September 2nd 2025

- Corrections applied on the measurements (thickness of membrane, shape of the probe)

- Determination of corrected measurements

- Obtention of shear resistance

- Use of a demo interpretation software

- Additional examples (Other ground types: sand, gravel, etc.)

September 3rd 2025, 09.00 to 10.30 : Utilisation of Ménard pressuremeter parameters

4. Use of Ménard pressuremeter parameters (Julien Habert)

- Overview of methods

- Ground classification

- Examples of foundation design

- Shallow foundations: Bearing capacity and settlements

- Deep foundations: Axial and transversal behaviour

- Micropiles

- Application based on tests performed on September 2nd 2025

Short course 2: Borehole Shear Tests by the Phicometer procedure

By Moulay ZERHOUNI & Robert HEINTZ

In-situ full scale tests demonstration on Belval site: September 2nd 2025 – 09.00 to 12.30

Courses: September 2nd 2025 – Time: 14:00 – 18:00 - including coffee break

General overview of the in-situ measurement of shear strength of soils

• Parameters characterizing shear strength of soils and how to determine them

• The main laboratory shear tests – Principles

• Bibliographical overview and principles of different types of existing in situ Borehole shear tests

• Overview of the new EN ISO 22476-16:2024 – Borehole shear test with the phicometer procedure (P-BST) “

Testing equipment and protocols

• Overview of the P-BST testing equipment and characteristics:

• The Phicometer probe, The Pressure-Volume Control Unit, The probe Pulling device

• Means of measurement and control: Pressure, Volume, Pulling force, shear displacement, time. Device prototype with automatic data logging and constant pulling speed control.

• Accuracy, Calibration and checks

• The Phicometer Borehole drilling phase

• Drilling techniques used to create the cylindrical test pocket

• Test pocket geometrical characteristics

• Phicometer testing program

• Flowchart of the P-BST test and successive phases to carry-out: Borehole drilling, Calibrations and checks, probe placement, the teeth insertion phase, the shearing phase

• Shear loading program according to the EN ISO 22476-16 and test-end criteria

• Test sheets and measurements to be recorded

Data-reduction procedures and P-BST test results

• Background and general principles and application to the Belval test carried out in the morning

• Corrections to apply: Volume – Diameter correction, hydrostatic correction and pressure loss correction

• Determination of the shear strength parameters and associated graphs

• Determination of the radial pressure

• Determination of the limit shear stress

• The different curves/graphs of a BST test

• Analysis of the results and graphs and determination of the significant zone of adjustment

• Determination of the in-situ shear strength parameters

• Presentation of the Results and Interpretation of the test carried out on September 2nd 2025 morning

• Raw measurements and calibrations curves

• Corrected curves and graphs obtained

• Choice of the significant adjustment zone and linear regression to obtain the friction angle and cohesion parameters

• Example of phicometer BST test report and test log

• Additional test examples (atypical tests, uncomplete tests, non-linear tests, etc.)

Use and Application of the P-BST in-situ shear strength parameters in projects

• Theoretical background

• Accuracy of phicometer results

• Points to be checked and Typical test anomalies that may appear

• Type of the P-BST shear strength characteristics: drained or undrained ?

• Comparison with the characteristics given by laboratory shear tests

• Correlations to obtain effective shear strength parameters (correlations by G. Philipponnat & M. Zerhouni)

• Some examples of the use of the P-BST in geotechnical design: retaining structures, slope stability, …

• Additional examples of P-BST: Tests in sand, gravel, cement or lime treated soils, MSW. Tests with automatic data logging and constant pulling speed control (presentations by R. Heintz, J-P. Baud & M. Zerhouni) “

Short course 3: High Pressure, High Resolution, Special Pressuremeter Testing

By Yasmin Byrne, Robert Whittle, Alexandre Lopes

In-situ full scale tests demonstration on Belval site: September 2nd 2025 – 09.00 to 12.30

Courses : September 3rd 2025 – 11h to 18h – Duration: 5 hours, including breaks

11h00 to 12h30

1. Introduction and Objectives (15 mins) (Yasmin Byrne)

• Context and value of PMT in rock engineering

• How PMT complements traditional lab testing and geophysics

• Why weak or weathered rock presents unique challenges and opportunities

2. Overview of Pressuremeter Technology (15 mins) (Yasmin Byrne)

• Types of pressuremeters: TexAM, Cambridge PMT, HPD, RPM, Solexpert etc.

• Deployment modes: pushed, pre-bored, and self-bored — suitability for different conditions

• Data resolution and applicability

• Tool selection for transitional materials and weak rock

3. Cavity expansion theory and interpretation in soils (1h) (Robert Whittle)

• Background

• Quantifying disturbance

• Stiffness – the importance of the unload/reload response

• Stress and strain dependency of stiffness

• The undrained test – analysis and modelling

• The drained test – analysis and modelling

• Special case – the pushed test”

12h30 to 14h00 - Launch break

11h00 to 12h30

4. Interpretation of PMT in Weak Rock (30 mins) (Yasmin Byrne)

• Distinguishing shear vs tensile failure modes

• Interpreting response curves for weathered rock, saprolites, and structured materials

• Deriving stiffness and strength: linearity, strain limits, and defining failure

• Effects of creep, cracking, and anisotropy

5. Case Study: Shaftbury shale – Focus on Stiffness (20 mins) (Yasmin Byrne)

• Project overview and PMT testing program

• PMT vs. lab vs. full-scale lateral load test comparison

• Calibration and interpretation: how PMT informed the design

• Limitations in stronger rock: relaxation, conformance, tool-rock interaction

• Practical lessons in test setup and data interpretation

6. In-situ Lateral Stress in Rock (20 mins) (Yasmin Byrne)

• Methods to estimate horizontal stress (σₕ) with and without shear failure

• Use of lift-off, BPC, creep, and synthesis techniques

• Research directions and discussion on uncertainty

7. Complementary Techniques and Combined Approaches (15 mins) (Yasmin Byrne)

• Integration with seismic testing (Vs/Vp) and NMR

• Building a complete G₀–Gᵤ degradation curve in rock

• Improving FE modeling inputs through combined methods”

15h30 to 16h00 - Coffee break

16h00 to 18h00

8. Case Study: Focus on Stiffness at Small Strains and Stiffness Decay (40 mins) (Alexandre Lopes)

• Determination of G0, Gs(pc) and 0.7 using hyperbolic methods

• Case of dense sands and OC clays, comparison to geophysics and lab tests

• Simulation using FE method and insights into the determination of parameters

9. Live test interpretation (1h) (Robert Whittle)

• The purpose of this section is to start with a file representing the measured field curve and to then process it using purpose written software. During the course of this, the participants will be asked to make the decisions , the intention being to show to what extent the analyst can influence the process.

• If possible, the data being analysed will be obtained from equipment demonstrations being conducted as part of ISP8. If this is not possible, then data will be provided – it will be imperfect data, because one of the aims is to show how sensible results can be obtained even when some aspects of the testing have not gone to plan.

10. Summary and Open Discussion (20 mins)

• Key takeaways: strengths and limitations of PMT in rock

• Guidelines for scoping advanced PMT in projects

• Open Q&A and participant discussion

Short course 4: Pressuremeter tests in Ground improvement

By Dr Babak Hamidi ,Mr Chrisopher Tinat ,Mr Paul Pandrea , Mr Jérôme Racinais, Mr Serge Varaksin,session leader

In-situ full scale pressuremeter and phicometer tests demonstration on Belval site: September 2nd 2025 – 09.00 to 12.30

Courses : September 3rd 2025 – 14h to 18h – Duration: 4 hours, including coffee break

14h00 to 14h35 - Introduction - Serge Varaksin, session leader

- Some international historical mile stones

- Luxemburg hospital

- Mandelieu France devellopement

- Taurn Autobahn Austria

- King Abdul university

- Tsin Yi oil terminal Hong Kong

- Introduction of speakers

14h35 to 15h30 - Further use of the pressuremeter in ground improvement - Dr Babak Hamidi, Chairman TC 211

- Creep and aging due to self-weight of fill

- Influence of soil straining on strength

- Predicting parameters using dynamic compaction induced subsidence.

- Verification model

- Discussion

16h00 to 16h35 - The Pressuremeter as quality control for ground improvement works - Mr Christopher Tinat, Technical director Menard GMBH

- The 4 classes of Eurocode 7-3

- Validation of ground improvement with suitable tests

- Pressuremeter parameters for class A1 and A11

- Class B11 case

- Recommendation for performance of pressuremeter tests after ground improvement

- Some specific applications

16h35 to 17h10 - Optimisation of design and execution of Ground Improvement based on the pressuremeter - Mr Paul Pandrea, Technical director Keller GMBH

- Comparison of CPT and pressuremeter results

- Limitations for full displacement systems, assessed with CPT and PMT

- Case study of a tank farm

- Comparison of deformation predictions with hydrotest results

- Conclusions & Recommendations

“

17h10 to 17h45 - The Pressuremeter as design tool for rigid inclusions - Mr Jérôme Racinais, Technical Director Menard

- Unification of calculation methods by ASIRI research program

- Value of the pressuremeter test in numerical and finite elements calculation methods

- ASIRI guide lines and recommendations

- Semi empirical models

- Comparison between prediction and actual observation

- Discussion